Cooling chamber subsoil protection

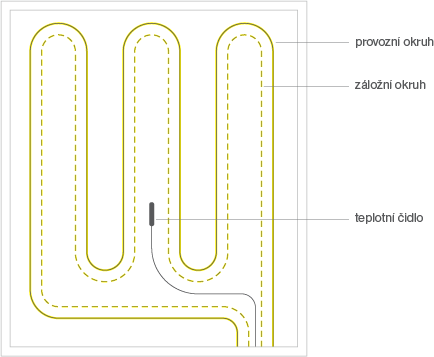

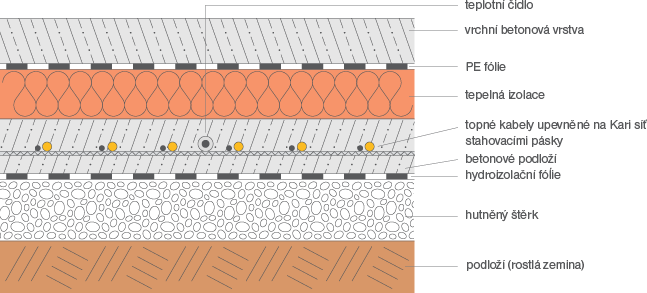

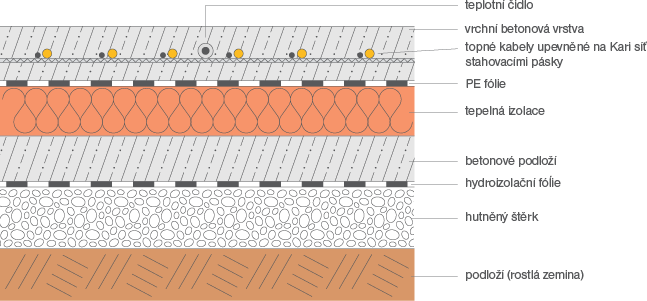

Despite the proper floor insulation of a cooling box, the base concrete and subsequently the subsoil can reach subzero temperatures due to the permanent very low temperatures. This phenomenon can cause cracks in the floor and foundations, disrupt the statics of the building and thus create great damage. Which is why heating cables of the FLEXFLOOR series, that will keep the subsoil temperature in non-freezing values are installed into the base concrete layer. As this system is constantly in operation, two heating circuits are installed to increase reliability (working and stand-by). The heating cables are mostly fixed with tightening strips onto a reinforcing KARI mesh, which also serves as a reinforcement of the base concrete. Heating is controlled by thermostats e.g. UTR or ITR with a sensor, that scans the temperature of the layer containing the heating cables. The necessary operational output is around 20 – 30 W/m2. To achieve even heating, we recommend to select the distance between heating cable maximally at 33cm.

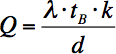

For the calculation of heat losses of the subsoil, we can use the following formula:

Q – heat loss of 1 m2 of plane surface [W/m2],

λ – coefficient of thermal conductance of insulation [W/m.K],

d – thickness of insulation in [m],

tB – min. temperature inside cold room [°C],

k – coefficient of unspecified heat losses, k=1.25.

Cooling chamber floor protection

When the door of the cooling chamber is opened, humid warm air from the outside mixes with the cold air inside. The generated condensation of air humidity will cause the creation of ice on the floor. Therefore a heating cables that will increase the surface temperature are installed in the area near the door. The heating cables are fixed similarly as in the subsoil, with tightening strips on to reinforcing KARI mesh, which also serves as a reinforcement. Heating is controlled by a thermostat, e.g. UTR or ITR with a sensor, which reads the subsoil temperature in the layer containing the heating cables. The necessary operational output is around 150 W/m2. Due to easier repair or exchange of the heating cable, it is not necessary to install a stand-by circuit.

KYCY – serial heating cable

A serial resistance heating cable, in addition equipped with a copper weave and outer thermoplastic jacket (PVC). It is used for floor heating, heating of outdoor areas (ramps, stairs, sidewalks, roads), heating of cooling chamber subsoils. It is supplied in length, REVOS though, can provide prepared heating loops with 3m cold feeds on both sides. This procedure enables to supply loops of any length, output and powering voltage. The nominal output is limited only by the maximal value in W/m.

KYCYR 10 W/m – serial heating cable with a regressive conductor

A serial resistance cable as the KYCY, only with a regressive conductor. It allows to create a blind end on one side by connecting the heating element and the regressive conductor, and to power the heating cable only at the other side. This facilitates the installation of the heating cable. KYCYR heating cables are supplied in a variety of lengths, outputs, terminated in production, with a 2.5m cold feed. They are primarily used for floor heating in residential and industrial objects.

Heating of doors and doorframes of cooling chambers

The temperature inside the cooling chamber is very low, and it causes the door to freeze to the doorframe due to the air humidity. When the door is forcefully opened, the silicone seal is damaged and has to be replaced. This can be prevented by installing a heating cable of the FLEXCORD or FLEXTAPE series, usually into the doorframe, and into the door if necessary. The recommended output is 20-30 W/m for 1m of the door perimeter. The cable is constantly heating without the need for any regulation.

C1S – silicone heating cord

It is a serial heating element with a defined resistance for 1 m of length. This cord is supplied in length and it is necessary to attach the cold feeds during installation. If the joints are not made properly, there is a danger of moisture getting inside and subsequent damage to the cable. If necessary, it is possible to fit the cable with a tin-plated copper braiding.

CS, CS1, CS2, CS3 – silicone heating cable with cold feeds

These cables derive from the C1S heating cord. They are supplied terminated from production in standard or required lengths, outputs and powering voltages.

FTS0 – heating cable with constant output and silicone insulation

This type of cable is always powered from one end and it is possible to shorten it at installation in multiples of 0.5m to a required length. Therefore, it is most often used in repairs and piece production. The cable is supplied in three output versions – 25, 40, 50 W/m and with the possibility of a tin-plated copper braiding.

Heating of drainpipes

The low temperature in cooling chambers is provided by evaporators, on which hoarfrost is created during operation. In certain time cycles, the evaporator is intensely heated by electrical heaters and the water from the melting ice is diverted through a drainpipe. As a section of the pipe may be endangered by the water freezing and subsequently damaging the evaporator, it is necessary to install a FLEXDRAIN heating cable into, or to the outside of the pipe. This cable is turned on and off simultaneously with the de-frosting cycle, which means that it is free of further regulators.

CSC – CSC/T – CSC/I – heating cables for drainpipes

CSC, CSC/T and CSC/I heaters are designated for placement into the drainpipe operating during melting of the cooling medium in the cooling chamber. They operate only during the de-frosting cycles. We´re talking about a special heating cable construction, where a regressive copper conductor is integrated into the heating cord. The blind end termination and the powering cable connection are protected by a silicone mould. Standardly, it is supplied in lengths from 1 to 25m.

CSC2 – drainpipe heater

The CSC2 heater consists of a heating cable with a cold feed, fully integrated with the heating section on one side. The start of the cold feed is marked by a sign on the cable. The blind end is insulated by a vulcanized silicon mould. The cabel is equipped with a double silicone insulation, making it resistant to temperatures from -70°C to 200°C.

CSC2K – drainpipe heater with a thermostat

The CSC2K heating cable derives from the CSC2 type, but in addition, it has a built-in thermostat at the blind end of the heating cable. The heater is designated for positioning in collecting tubs of heat pumps and in cooling chambers. The built-in thermostat initiates the heating based on the environment temperature, so the heater can function independently on the other devices.

FTS0 – heating cable with constant output and silicone insulation

This type of cable is alwys powered from one end, and it is possible to shorten it at installation in multiples of 0.5m to a required length. Therefore, it is most often used in repairs and piece production. The cable is supplied in three output versions – 25, 40, 50 W/m and with the possibility of a tin-plated copper braiding.

FSG – auto-regulating heating cable

An auto-regulating heating cable for light industrial applications, construction and home use for anti-frost protection and maintenance of low temperatures.