![]()

The Hill's plant was being constructed by Kovoprojekta Brno with the highest reliability and responsibility for which it is known from other industrial projects.

A feed production plant also needs its logistic support. The logistics of raw materials and finished goods requires a sufficient number of docking gates. To ensure that the load areas of trucks are leveled with the production hall floor, driveways leading to the docks must have an apropriate slope. This slope can become dangerous during unfavourable weather conditions for the docking trucks. This led to the idea of heating the critical surfaces of the driveways with heating cables.

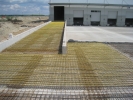

The heating installation was assigned to the REVOS company. ,REVOS has years of experience installing heating cables, especially in external surfaces. The heated area in Hill’s Hustopeče is almost 2600 sq.m. Originally, the driveway was to include tarmac surface. The constructor, however, concluded this would lead to deformation from heavy traffic and decided to replace the tarmac with concrete.

The installed output reaches 604 kW. To distribute such high amounts of heat to the entire surface, we used 4 supply shaft placed into the heated surface. The surface had been divided into 70 dilatation parts and each of them includes an installation of 9 kW of heating output. The overall length of the FLEXELEC heating cable series FLEXFLOOR is 21,5 km.

„The detektor of snow and ice“ is based on temperature and moisture sensor evaluating the weather conditions at any moment ands optimally regulates the heating system. This leads to maximal electric energy savings. Heating is turned on only when snow or ice is present and upon melting it is turned off.

We wish the Hill's Hustopeče company years of problem-free operations.